Throughout the environment of factory methods, maintaining the entirety and effectiveness of lines is necessary. Amassing of residue within tubes can notably retard fluid movement, reduce product quality, and adds to facility expenses. To deal with these problems, pipeline cleaning processes have surfaced as exceptionally capable remedies for effective duct cleansing. A device, habitually a circular device, is transported through the duct, effectively eradicating accumulations and attaining best productivity

Pigging systems strategies provide plentiful pros. They are resourceful, suitable for sterilizing ducts of varied dimensions and content. Furthermore, they are potent, executing the work in a comparatively brief length. By minimizing downtime and optimizing pipeline capacity, pipeline cleaning systems encourage price drops and amplified operational performance

Cleanliness Pipeline Practices:

Safeguarding pipeline purity is fundamental for backing commodity integrity and value of transported items. Sanitary pigging technologies extend a stable way to attain this intention. Pigs, specific devices, are deployed into pipelines to scrub by getting rid of residues and impurities

- Diverse categories of sanitary pigs exist, each engineered for special cleaning purposes.

- These pigs are created from materials that conform to stringent antiseptic standards.

- Frequent sanitary pigging operations assist warding off product spoiling, preserve pipeline functional period, and boost aggregate capability.

Progressive Pigging Technologies for Optimal Effectiveness

pigging productsThroughout the sphere of line support, high-tech pigging technologies have emerged as a vital resource for ensuring superior efficiency and preservation. These revolutionary systems exploit clever arrangements and performances to productively disinfect, analyze, and preserve channels from corrosion. From advanced pigs provided with live observation components to custom pigging devices meant for complex tasks, growth in this branch is uninterruptedly surpassing limits. By exploiting these novelties, handlers can greatly enhance pipeline sturdiness, lower downtime, and heighten operational output.

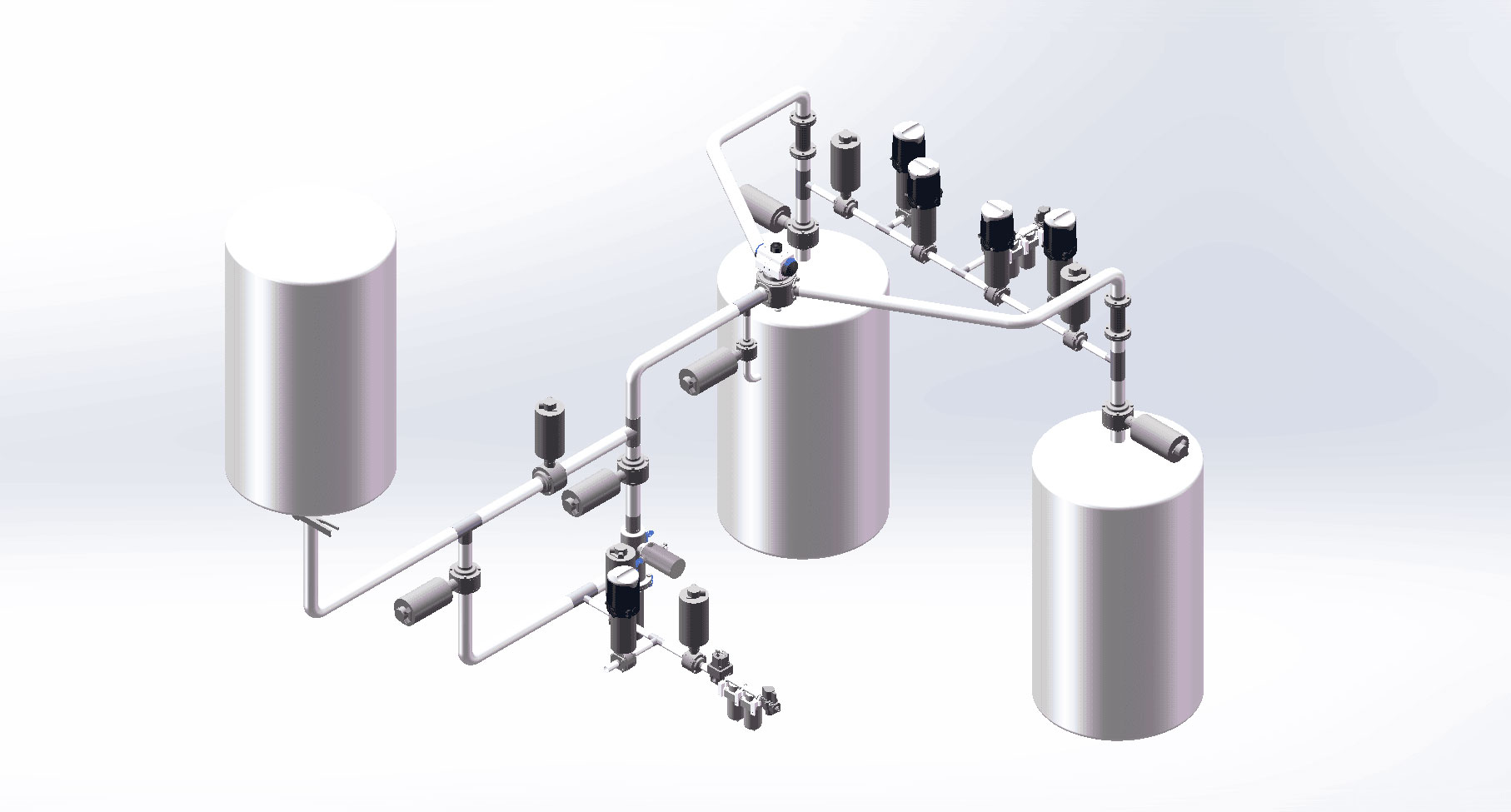

Broad Pigging Setup Engineering and Setup

An full-scale pigging system incorporates a key strategy for pipeline upkeep. This method entails the deployment of specialized mechanisms called pigs, which migrate through lines to sterilize, assess, and maintain their firmness. The structure highlights aspects such as pipe size, composition, pig style, and operational criteria. A well-designed system warrants competent pigging tasks while lessening downtime and potential breakdowns. Installation customs call for careful organization, skilled craftsmen, and strict adherence to safety standards to warrant a stable and effective achievement

Commercial Pigging Systems for Extensive Assignments

Heavy-Duty pigging gadgets are essential assets deployed across a wide collection of industries. These mechanisms support satisfactory and successful disinfecting, survey, and conservation of lines and other hollow assemblies. Pigging embraces introducing dedicated tools known as pigs through pipes to complete multiple functions. Classic types of industrial pigging tools contain cleaning pigs, inspection pigs, and distribution pigs. Cleaning pigs are made to wipe off debris, build-up, and unwanted substances from pipelines. Inspection pigs are supplied with measuring tools that collect information about the quality of pipe bases. Transport pigs are utilized to transport products through pipelines. The use of industrial pigging products contributes numerous advantages, such as curtailed downtime, augmented pipeline steadfastness, and heightened operational performance. These apparatuses are frequently utilized in domains such as oil and gas, water treatment, chemical production, and food manufacturing.A Detailed Guide to Pipeline Pigging

Pipeline pigging is an indispensable approach used within the oil and gas arena to audit pipelines. This necessary operation entails injecting specific implements, referred to as pigs, into the conduit. Pigs are built to pass through the distance of the pipeline, accomplishing various responsibilities.

Multiple kinds of pigs are accessible, each specialized for a particular goal. Common functions of pipeline pigging entail testing for defects, scrubbing, and surface treatment.

- Upsides of Pipeline Pigging

- Outcomes on Operational Efficiency

- Segments of Pipeline Pigs

Established Sanitation utilizing Pigging Setups

Pigging solutions contribute a stable answer for promoting sanitation inside passages. These mechanisms leverage unique apparatuses that flow through the line arrangement, adroitly scrubbing accumulation. The technique is especially useful for sectors that demand rigorous spotlessness benchmarks. Pigging technologies grant a affordable and timely approach for cleaning passages, diminishing the threat of infection.

Choosing Pigging Equipment for Custom Conditions

Pigging tools serves a significant role in competent pipeline performance. When selecting pigging equipment, it is necessary to consider the individual requirements of your assignment. This embraces examining aspects such as pipeline extent, flow volume, product type, and overhaul demands.

Various pigging forms are present, each designed for distinct objectives. Such as, some pigs are meant for assessment, while others are deployed for eliminating pollutants or segmenting product groups.

What's more, pigging apparatus items should be harmonious with the transported carrier.

It is frequently optimal to collaborate with a engineer in pigging methods to secure that you elect the most proper tool for your distinct criteria.

Inline Cleaning Technologies - A Profit-Driven Approach

Pipeline tools grant a broad choice of advantages for markets working with pipes. By skillfully sanitizing and reviewing internal pipelines, pigging systems boost operational capability and curtail maintenance budgets.

A main positive of pigging systems is their skill to eliminate fouling such as dirt, debris, and decay products. This scheduled sanitation promotes frictionless pipeline passage and reduces costly downtime.

Furthermore, pigging systems can be applied to survey the quality of pipelines, identifying prospective faults before they spread into serious threats. This preemptive process helps to increase longevity of pipelines and lower overall maintenance charges.

Safeguarding Hygiene in Pigging Workflows

Pig husbandry methods fundamentally trust appropriate hygiene guidelines to restrain the transmission of diseases. Adopting rigorous hygiene measures maintains a sound habitat for pigs, thus generates optimal health outcomes and functionality.

Detailed cleaning and disinfection of premises is vital to control the presence of harmful pathogens. Adequate waste management furthermore serves a major part in maintaining hygiene.

Additionally, {workers