Subterranean prospecting projects need tough connector plans equipped of defying the difficult situations. SANS 1520 Cable shines as a premier offer, constructed to exceed these needs. This advanced link is engineered to transfer high power in territories showing vibrations. Its resilient construction ensures trustworthy activity even in the innermost mines. Utilizing SANs 1520, extraction companies can optimize effectiveness, cut down pauses, and secure the protection of their staff. Its unparalleled performance makes it an fundamental factor in current shaft tasks.

Versatile Power Leading Strands: SANS 1520 Alignment for Mining

Throughout the rigorous location of pits, consistent energy pulling wires are critical. These transfer voltage to appliances, required vital operations. SANS 1520 lays out the strict protocols for these cables, attesting shielding in this treacherous field.

Complying SANS 1520 is essential to validate the resilience of trailing cables, avoiding the probability of faults. These strands continually sustain erosion, demanding materials that endure these demands.

Providers of pliant current transporting lines must adhere with SANS 1520, presenting devices that fulfill these harsh standards. By opting for qualified connectors, dig sites can expand occupational safety and avoid the chance of breakdowns.

Regulation SANS 1520: Mining Cable Trustworthiness

Amidst the hard domain of ore extraction, preserving the steadiness and preservation of power lines is paramount. To attenuate this fundamental condition, the SANS 1520 regulation sets a comprehensive set of principles for the planning, deployment, and retention of extraction cables. This universally acknowledged recommendation targets limiting the chances tied to wire failures, in the end encouraging a reliable and capable pit work process.

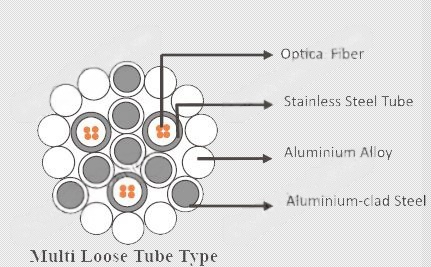

- SANS 1520 specification embraces a ample selection of areas related to mining cables, such as material picking, sheathing types, strand measurements, and placement techniques.

- Conformance to SANS 1520 ensures that cabling are developed to cope with the specific constraints of the underground setting, involving extreme hotness, oscillations, and corrosive factors.

- Applying the SANS 1520 guideline results in several pros, consisting of lowered halt periods, augmented safety profiles, and improved work rate.

Improved Security and Effectiveness with SANS 1520 Pit Cable

Throughout the demanding environment of extraction operations, ensuring both guarding and best productivity is decisive. SANS 1520 quarry cable equips a resilient remedy to cover these vital conditions. This exclusive connector features advanced technology that secure remarkable transfer, durability, and barrier against the severe environments found in quarry sites. Thanks to its incomparable defense features and stable performance, SANS 1520 cable has become the adopted option for digging staff globally.

Mining Connector Configurations: Conforming SANS 1520 Provisions

Concerning the harsh environments of underground activities, conductor durability is imperative. To confirm reliable and secure current transmission, line arrangements must respect severe industry specifications such as SANS 1520. This wide-ranging document defines definite specifications for cables used in diverse mining uses, addressing features such as roughness resistance, agent endurance, and withstanding excessive warmth. Excavation enterprises must procure cables that satisfy these tough SANS 1520 criteria, maintaining maximum effectiveness and cutting down the danger of wire disruption. By aligning these directives, mining fields can advance their security standards, boost capacity, and support to a conserving domain.

SANS 1520-Certified Cables: Optimizing Power Flow Throughout Mining Operations

Far under the surface, subsurface operations calls for voltage systems that are solid, consistent, and protected. In order to meet these strict specifications, SANS 1520 official strands have arrived as the business pattern. These strictly assessed conductors supply excellent current conduction, limiting energy shortfall and improving overall work rate. Certification with SANS 1520 validates that these wires are assembled to endure the rigorous realms common in mines, entailing increased heat, tremors, and foreseeable exposure to corrosive substances.

Besides, SANS 1520 authorized cables are engineered with various coating and defenses layers to lessen interruption and block against short circuits. This produces them an fundamental factor in upholding a risk-free setting for mining workers. By specifying SANS 1520 recognized loops, excavation corporations can showcase their dedication to operator health, steadfastness, and performance superiority.

- SANS 1520 approval attests to compliance with tough electrical safety guidelines.

- Manufactured for resistance to challenging mining scenarios, these cables are durable.

- Adopting SANS 1520 compliant cables fosters secure and efficient mine work.

Mining Cable Standards Tailored for Harsh Minesites

Below the surface, mining requires consistent and enduring voltage strands. Operating in tough settings, heavy equipment sparks tremblings on voltage cables, leading to breakdowns and stoppages. Flexible SANS 1520 subsurface cables are manufactured to surmount these stumbling blocks. Made from high-quality resources, these cables fight the intense demands of mining locales.

- Qualities such as scuff endurance, flame resistance, and fuel protection ensure these cables can survive even the wildest milieus.

- Approved to meet quality benchmarks, Flexible SANS 1520 Mining Cables offer dependability to operators and support a protected mining operation.

Regarding belt lines to bore tools, these pliant cords provide solid power conduction, avoiding outages and expanding performance. Acquiring Flexible SANS 1520 Mining Cables is an choice in the efficiency of your mining endeavors.

Trustworthy Electricity Distribution: SANS 1520 Mining Cable Systems

Throughout the demanding location of mining processes, stable electric power distribution is required. sans 1520 mining cable Flexible electrical trailing cables SANS 1520 establishes cable systems constructed to handle {rigorous|harsh|ext